The motor can be started manually with a rheostat, offering a simple yet effective method for controlling the starting current of electric motors. This technique has been widely employed in various industrial and commercial applications, providing advantages over other starting methods in specific scenarios.

In this comprehensive guide, we delve into the intricacies of manual motor starting using rheostats. We explore the construction, operation, and step-by-step procedure involved in this process, highlighting its advantages and disadvantages compared to alternative starting mechanisms.

1. Motor Starting Mechanisms

Manual starting with a rheostat is a method of starting an electric motor by manually controlling the flow of current into the motor’s windings. This is achieved by using a rheostat, which is a variable resistor that can be adjusted to limit the current flowing through the circuit.

The main advantage of manual starting with a rheostat is that it allows for a gradual increase in current, which reduces the mechanical stress on the motor and its components. This can be particularly important for large or high-inertia motors.

However, manual starting with a rheostat also has some disadvantages. First, it requires a skilled operator to ensure that the current is increased gradually and safely. Second, it can be time-consuming, especially for large motors.

Manual starting with a rheostat is commonly used in applications where the motor is started infrequently or where a gradual increase in current is required to avoid damage to the motor or its components. Some examples of such applications include:

- Large industrial motors

- High-inertia motors

- Motors in hazardous environments

2. Rheostat Construction and Operation

A rheostat is a variable resistor that is used to control the flow of current in a circuit. It consists of a resistive element, which is typically made of wire or carbon, and a sliding contact that can be moved to change the resistance of the circuit.

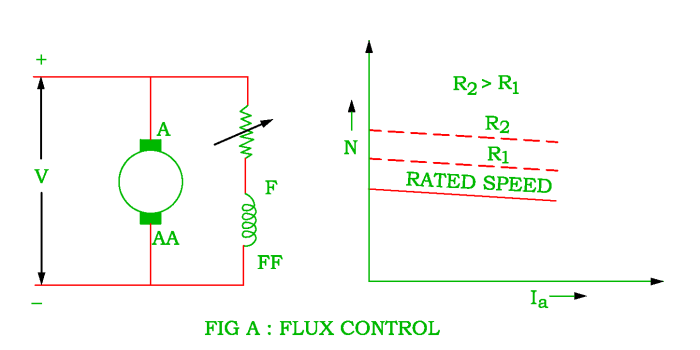

When the sliding contact is moved to increase the resistance, the current flowing through the circuit decreases. Conversely, when the sliding contact is moved to decrease the resistance, the current flowing through the circuit increases.

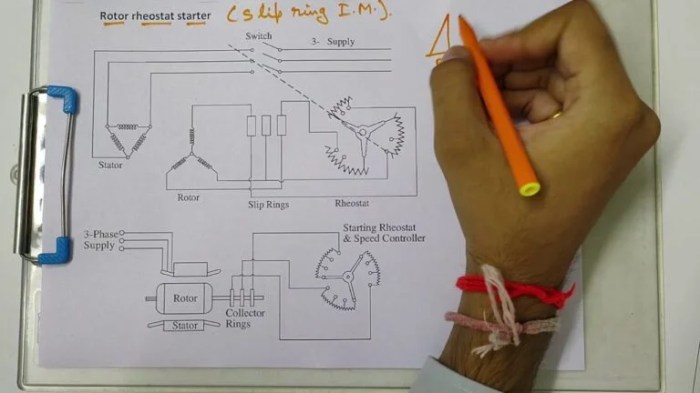

In a motor starting circuit, a rheostat is connected in series with the motor. When the motor is started, the rheostat is set to its maximum resistance. This limits the current flowing through the motor to a safe level.

As the motor accelerates, the rheostat is gradually adjusted to decrease the resistance. This allows the current flowing through the motor to increase, which in turn increases the torque produced by the motor.

Once the motor has reached its full speed, the rheostat is removed from the circuit. This allows the motor to operate at its full current and torque.

The following diagram shows the connection of a rheostat in a motor starting circuit:

3. Starting Procedure

The following is a step-by-step procedure for starting a motor manually with a rheostat:

- Ensure that the motor is properly connected to the power supply.

- Set the rheostat to its maximum resistance.

- Close the main circuit breaker.

- Slowly move the rheostat’s sliding contact to decrease the resistance.

- Monitor the motor’s current and speed.

- Once the motor has reached its full speed, remove the rheostat from the circuit.

The following table summarizes the starting procedure:

| Step | Action |

|---|---|

| 1 | Ensure that the motor is properly connected to the power supply. |

| 2 | Set the rheostat to its maximum resistance. |

| 3 | Close the main circuit breaker. |

| 4 | Slowly move the rheostat’s sliding contact to decrease the resistance. |

| 5 | Monitor the motor’s current and speed. |

| 6 | Once the motor has reached its full speed, remove the rheostat from the circuit. |

It is important to observe the following safety precautions when starting a motor manually with a rheostat:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Ensure that the motor is properly grounded.

- Do not touch any live electrical components.

- Do not start the motor if it is damaged or if there is any evidence of a fault.

4. Troubleshooting: The Motor Can Be Started Manually With A Rheostat

The following are some common problems that can occur during manual starting with a rheostat:

- The motor does not start.This could be due to a number of factors, including a faulty rheostat, a problem with the motor’s windings, or a problem with the power supply.

- The motor starts but does not reach full speed.This could be due to a problem with the rheostat, a problem with the motor’s windings, or a problem with the load.

- The motor runs but makes a loud noise.This could be due to a problem with the motor’s bearings, a problem with the motor’s windings, or a problem with the load.

The following table provides some troubleshooting tips for manual starting with a rheostat:

| Problem | Possible Cause | Troubleshooting Tip |

|---|---|---|

| The motor does not start. | Faulty rheostat | Check the rheostat for any damage or loose connections. |

| The motor does not start. | Problem with the motor’s windings | Check the motor’s windings for any damage or loose connections. |

| The motor does not start. | Problem with the power supply | Check the power supply for any problems, such as a blown fuse or a tripped circuit breaker. |

| The motor starts but does not reach full speed. | Problem with the rheostat | Check the rheostat for any damage or loose connections. |

| The motor starts but does not reach full speed. | Problem with the motor’s windings | Check the motor’s windings for any damage or loose connections. |

| The motor starts but does not reach full speed. | Problem with the load | Check the load for any problems, such as a jammed mechanism or a broken belt. |

| The motor runs but makes a loud noise. | Problem with the motor’s bearings | Check the motor’s bearings for any damage or wear. |

| The motor runs but makes a loud noise. | Problem with the motor’s windings | Check the motor’s windings for any damage or loose connections. |

| The motor runs but makes a loud noise. | Problem with the load | Check the load for any problems, such as a jammed mechanism or a broken belt. |

FAQ Summary

What is the primary advantage of using a rheostat for motor starting?

Rheostats allow for gradual acceleration of the motor, reducing the starting current and minimizing mechanical stress on the motor and its components.

What safety precautions should be observed during manual motor starting with a rheostat?

Always wear appropriate personal protective equipment, ensure proper grounding, and follow established safety protocols to prevent electrical hazards.

Can rheostats be used to start all types of electric motors?

No, rheostats are primarily suitable for starting AC induction motors. Other motor types may require different starting methods.