The originator is different from the shipper – In the realm of supply chain management, the roles of the originator and the shipper are often distinct, yet interconnected. This article delves into the fundamental differences between these two entities, exploring their responsibilities, the factors contributing to their disparity, and the implications of their separation.

The originator, the entity responsible for creating or acquiring goods, may differ from the shipper, the party tasked with transporting those goods to their destination. Understanding these distinctions is crucial for optimizing supply chain efficiency and customer satisfaction.

Originator vs. Shipper: Core Differences

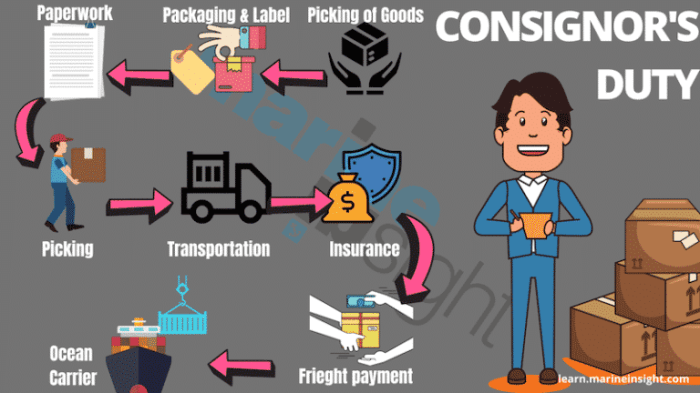

The originator and the shipper are two distinct entities in the supply chain, each with its own unique roles and responsibilities. The originator is the entity that creates the goods or products, while the shipper is the entity that transports the goods to the customer.

This fundamental distinction in their functions gives rise to several key differences between the two parties.

One of the most significant differences between the originator and the shipper lies in their level of involvement in the production process. The originator is directly responsible for the design, development, and manufacturing of the goods. This involves a high level of expertise and technical knowledge, as well as a deep understanding of the product’s intended use and market demand.

The shipper, on the other hand, is not involved in the production process and is primarily concerned with the transportation and logistics aspects of the supply chain.

Another key difference between the originator and the shipper is their relationship with the customer. The originator typically has a direct relationship with the customer, as they are the ones who create the product that the customer purchases. This relationship allows the originator to gather feedback from the customer and make adjustments to the product accordingly.

The shipper, on the other hand, typically does not have a direct relationship with the customer and is primarily responsible for ensuring that the goods are delivered to the customer in a timely and efficient manner.

Reasons for Disparity: Originator vs. Shipper

The disparity between the originator and the shipper can be attributed to a number of factors, including the nature of the product, the size and complexity of the supply chain, and the regulatory environment.

In some cases, the originator and the shipper may be the same entity. This is often the case for small businesses that produce and sell their own products. However, as businesses grow and their supply chains become more complex, it becomes more common for the originator and the shipper to be separate entities.

This is because the specialization of labor allows each party to focus on their core competencies and achieve greater efficiency.

The size and complexity of the supply chain can also contribute to the disparity between the originator and the shipper. In a simple supply chain, the originator may be able to handle both the production and transportation of the goods.

However, in a complex supply chain, the transportation of the goods may require specialized expertise and infrastructure. This is often the case for products that are shipped internationally or that require special handling.

Finally, the regulatory environment can also impact the relationship between the originator and the shipper. In some countries, there are strict regulations governing the transportation of goods. These regulations may require the shipper to obtain special licenses or permits, or to comply with specific safety standards.

This can add complexity to the shipping process and further differentiate the roles of the originator and the shipper.

Implications of the Difference

The separation of the originator and the shipper has a number of implications for supply chain management, logistics, and customer experience.

In terms of supply chain management, the separation of the originator and the shipper can lead to increased complexity and coordination challenges. This is because the two parties need to work together closely to ensure that the goods are produced and shipped in a timely and efficient manner.

This can be especially challenging in complex supply chains that involve multiple tiers of suppliers and distributors.

In terms of logistics, the separation of the originator and the shipper can lead to increased costs and inefficiencies. This is because the two parties may have different priorities and objectives, which can lead to conflict and delays. For example, the originator may prioritize the production of high-quality goods, while the shipper may prioritize the speed and cost of transportation.

This can lead to tension between the two parties and make it difficult to achieve optimal logistics performance.

In terms of customer experience, the separation of the originator and the shipper can lead to reduced visibility and control for the customer. This is because the customer may not have a direct relationship with the shipper and may not be able to track the status of their order or make changes to it.

This can lead to frustration and dissatisfaction for the customer.

Benefits of Alignment: Originator and Shipper

Despite the challenges that can arise from the separation of the originator and the shipper, there are also a number of potential benefits to having the two parties work closely together.

One of the main benefits of alignment between the originator and the shipper is improved supply chain efficiency. When the two parties are aligned, they can work together to identify and eliminate inefficiencies in the supply chain. This can lead to reduced costs, improved lead times, and increased customer satisfaction.

Another benefit of alignment between the originator and the shipper is improved logistics performance. When the two parties are aligned, they can work together to develop and implement logistics solutions that meet the needs of both parties. This can lead to reduced transportation costs, improved transit times, and increased flexibility.

Finally, alignment between the originator and the shipper can lead to improved customer experience. When the two parties are aligned, they can work together to provide customers with a seamless and consistent experience. This can lead to increased customer satisfaction, loyalty, and repeat business.

Case Studies: Originator vs. Shipper

There are a number of real-world examples of situations where the originator and the shipper are different entities.

One example is the relationship between Apple and Foxconn. Apple is the originator of the iPhone, while Foxconn is the shipper. Apple designs and develops the iPhone, while Foxconn manufactures and assembles the device. This relationship has been successful because the two companies have worked closely together to align their goals and objectives.

This has led to the production of a high-quality product that is delivered to customers in a timely and efficient manner.

Another example is the relationship between Nike and FedEx. Nike is the originator of athletic shoes and apparel, while FedEx is the shipper. Nike designs and develops its products, while FedEx transports the products to retailers and customers. This relationship has been successful because the two companies have worked closely together to develop and implement logistics solutions that meet the needs of both parties.

This has led to reduced transportation costs, improved transit times, and increased flexibility.

Industry Best Practices: Originator and Shipper Collaboration: The Originator Is Different From The Shipper

There are a number of industry best practices that can be used to improve collaboration between the originator and the shipper.

One best practice is to establish a clear and concise communication plan. This plan should Artikel the frequency and methods of communication between the two parties. It should also identify the key stakeholders who will be involved in the communication process.

Another best practice is to develop a joint planning process. This process should involve both the originator and the shipper in the development of supply chain and logistics plans. This will help to ensure that the two parties are aligned on their goals and objectives.

Finally, it is important to establish a performance management system. This system should be used to track and measure the performance of the supply chain and logistics processes. This will help to identify areas for improvement and ensure that the two parties are working together to achieve their goals.

Essential FAQs

What are the key differences between the originator and the shipper?

The originator is responsible for creating or acquiring goods, while the shipper is responsible for transporting those goods to their destination.

What factors contribute to the difference between the originator and the shipper?

Factors such as the type of goods, the distance to be shipped, and the desired delivery time can all influence the roles and responsibilities of the originator and the shipper.

What are the implications of having the originator and the shipper being different entities?

This separation can impact supply chain management, logistics, and customer experience, both positively and negatively.