Nfpa 13 air compressor requirements – The National Fire Protection Association (NFPA) 13 standard establishes comprehensive requirements for the installation, maintenance, and operation of air compressors, ensuring safety and reliability in various industrial and commercial applications. This guide delves into the key provisions of NFPA 13, providing valuable insights for engineers, contractors, and facility managers responsible for air compressor systems.

NFPA 13: General Requirements

NFPA 13 is a comprehensive standard that establishes the minimum requirements for the installation, operation, and maintenance of air compressors and compressed air systems. It aims to prevent accidents and injuries associated with these systems, ensuring the safety of personnel and property.

Key definitions and terms used in NFPA 13 include:

- Air compressor: A device that converts mechanical energy into potential energy by compressing air.

- Compressed air system: A system that includes an air compressor, piping, and other components used to store, distribute, and utilize compressed air.

- Receiver: A vessel used to store compressed air.

- Safety relief valve: A valve that automatically opens to relieve excessive pressure in a system.

NFPA 13 Artikels general requirements for air compressor installations, including:

- Air compressors shall be installed in accordance with the manufacturer’s instructions.

- Air compressors shall be located in a well-ventilated area that is free from excessive heat, moisture, and dust.

- Air compressors shall be mounted on a solid foundation that is capable of supporting the weight of the compressor and its components.

Air Compressor Room Design

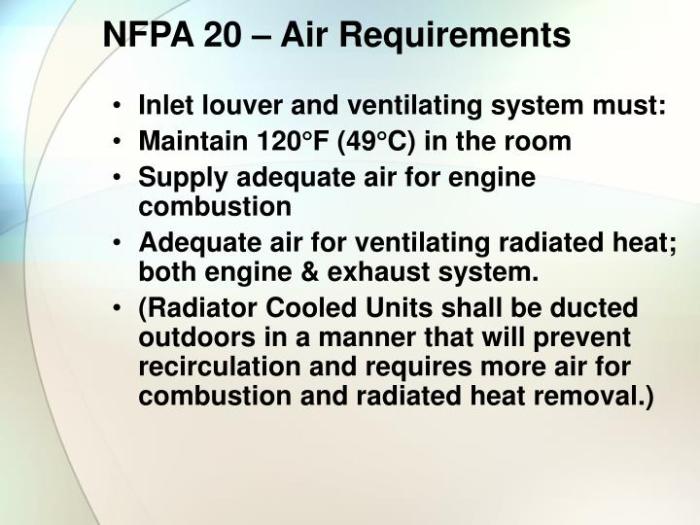

Air compressor rooms should be designed to provide adequate ventilation, lighting, and access for maintenance and inspection. Ventilation systems should be capable of removing heat, moisture, and contaminants from the room.

Lighting should be adequate for safe operation and maintenance of the air compressor and its components. Access to the air compressor and its components should be provided for maintenance, inspection, and repair.

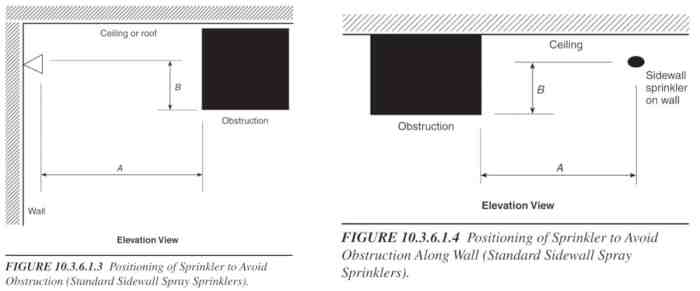

Fire protection systems, such as automatic sprinklers or fire extinguishers, should be installed in air compressor rooms to protect against the risk of fire.

Air Compressor Installation

Air compressors should be installed in accordance with the manufacturer’s instructions and the requirements of NFPA 13.

Air compressors should be mounted on a solid foundation that is capable of supporting the weight of the compressor and its components. Piping should be properly sized and installed to minimize pressure drop and ensure efficient operation of the system.

Electrical connections should be made in accordance with the National Electrical Code (NEC) and the manufacturer’s instructions. All electrical connections should be properly insulated and protected from damage.

After installation, air compressors should be tested and inspected to ensure proper operation and compliance with NFPA 13.

Air Compressor Maintenance: Nfpa 13 Air Compressor Requirements

Regular maintenance is essential to ensure the safe and efficient operation of air compressors. A recommended maintenance schedule should be established and followed to address the following tasks:

- Inspect air compressors regularly for leaks, damage, and wear.

- Replace air filters regularly to prevent contamination of the compressed air.

- Lubricate air compressors according to the manufacturer’s instructions.

- Test safety relief valves annually to ensure proper operation.

Regular inspections and repairs can help to identify and address potential problems before they become major issues.

Safety Considerations

Air compressors can pose several potential hazards, including:

- Explosion

- Fire

- Electrical shock

- Noise

- Pinch points

To prevent accidents and injuries, the following safety precautions should be taken:

- Train personnel on the safe operation and maintenance of air compressors.

- Wear appropriate personal protective equipment (PPE), such as safety glasses, hearing protection, and gloves, when working with air compressors.

- Follow all manufacturer’s instructions and warnings.

- Inspect air compressors regularly for leaks, damage, and wear.

- Keep air compressors clean and free of debris.

Question & Answer Hub

What is the purpose of NFPA 13?

NFPA 13 establishes minimum requirements for the installation, maintenance, and operation of air compressors to prevent fires and explosions and ensure safe operation.

What are the key definitions in NFPA 13?

NFPA 13 defines essential terms such as “air compressor,” “receiver,” and “safety relief valve” to ensure clarity and consistency in understanding.

What are the general requirements for air compressor installations?

NFPA 13 Artikels general requirements for the location, ventilation, lighting, and access to air compressor installations to ensure proper operation and maintenance.

What are the specific requirements for air compressor room design?

NFPA 13 provides specific guidance on the design of air compressor rooms, including ventilation, lighting, and fire protection systems, to minimize the risk of fires and explosions.

What are the maintenance requirements for air compressors?

NFPA 13 establishes a recommended maintenance schedule for air compressors, including regular inspections, repairs, and testing, to ensure optimal performance and safety.